Talk.Build - for the best Commercial Construction Blogs

Looking for the best construction blogs to stay ahead of the curve in the ever-evolving built environment? Talk.Build is your ultimate destination with thousands of different commercial construction blogs to choose from, with more added nearly every day. We serve as a vibrant online forum, to help foster knowledge and exchange views between seasoned industry veterans, emerging talents, and passionate construction enthusiasts.

Check out our extensive Commercial Blog Library: Dive into our expansive library featuring thousands of commercial construction blogs, meticulously categorized and continually updated with fresh content. Diverse Subject Matter: Explore a comprehensive range of topics spanning project management, safety regulations, sustainable construction practices, and cutting-edge building technologies. Expert-Driven Insights: Gain invaluable knowledge from industry leaders who share their practical experience with materials, tools, construction techniques, current design trends, and successful business strategies.

Check out The Feed for construction news in real time.

Building global solutions to combat water scarcity

As part of a major initiative to combat escalating water scarcity, Spain is set to inject €340 million into the construction of Africa's largest desalination plant in Casablanca. This ambitious...

Read moreDoes green steel represent a sustainable future for construction?

Steel and its strength, durability and versatility has made it an indispensable material for centuries, yet, it comes at a significant environmental cost. Traditional steel production is a major...

Read more

How AI robots are revolutionising Australian solar farm construction

Australia continues to build massive solar farms, vital infrastructure in the nation's transition to renewable energy. However, the sheer scale of these projects presents significant logistical and...

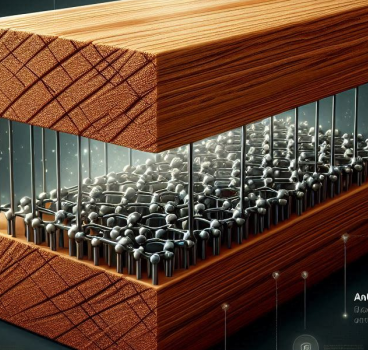

Read moreStrengthening wood with nano-iron is set to change construction

Researchers at Florida Atlantic University, in collaboration with the University of Miami and Oak Ridge National Laboratory, have developed a revolutionary method to strengthen wood at the cellular...

Read more

The growing threat of battery storage fires

The devastating Moss Landing Power Plant fire in California was global news and fed into concerns over the safety of Battery Energy Storage Systems (BESS). The January 16th blaze destroyed a...

Read moreUK brick shortages and the rise of timber construction

The UK housing sector and the government's ambition to deliver 1.5 million new homes by 2029 is running headfirst into an uncomfortable reality - a shortage of bricks and skilled bricklayers. This...

Read more

The secret life of scaffolding and its role in urban art

For centuries, scaffolding has been the unseen backbone of construction, maintenance and restoration projects across the globe. Temporary by design, functional in nature and rarely noticed unless as...

Read moreThe environmental impact of new construction and what it means for the industry’s future

New construction is a driving force in modern development but also brings undeniable environmental challenges. As a construction professional, you should understand these projects’ impact and explore...

Read more

Dry construction and a future with no concrete, no plaster and no mortar

For decades, the construction industry has relied on water-intensive processes to build the homes, schools, hospitals and infrastructure that shape our lives. Wet concrete, plaster, mortar and other...

Read more