Talk.Build - for the best Commercial Construction Blogs

Looking for the best construction blogs to stay ahead of the curve in the ever-evolving built environment? Talk.Build is your ultimate destination with thousands of different commercial construction blogs to choose from, with more added nearly every day. We serve as a vibrant online forum, to help foster knowledge and exchange views between seasoned industry veterans, emerging talents, and passionate construction enthusiasts.

Check out our extensive Commercial Blog Library: Dive into our expansive library featuring thousands of commercial construction blogs, meticulously categorized and continually updated with fresh content. Diverse Subject Matter: Explore a comprehensive range of topics spanning project management, safety regulations, sustainable construction practices, and cutting-edge building technologies. Expert-Driven Insights: Gain invaluable knowledge from industry leaders who share their practical experience with materials, tools, construction techniques, current design trends, and successful business strategies.

Check out The Feed for construction news in real time.

How Algae can be used as a living insulation material

In the search for sustainable building solutions, one unlikely candidate is beginning to attract attention - algae. While commonly associated with ponds, oceans, or even health supplements, algae has...

Read moreA 2026 reminder about the benefits of upgrading to LED lighting in the office

Modern workplaces are constantly evolving, with companies seeking ways to improve efficiency, reduce costs and create healthier, more productive environments for their teams. One of the...

Read more

Three Top Trends in Residential Building for 2026

Practicality is a prevailing theme in homebuying. Many people enter the housing market with a long-term approach, considering both current and future lifestyle needs to get the most out of their...

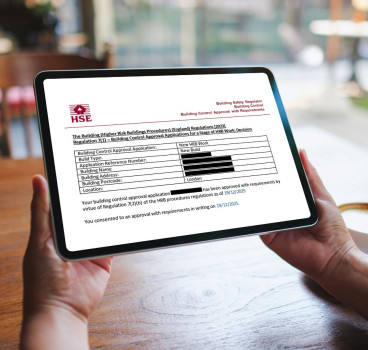

Read morePassing Gateway Two: What you need to know from an MEP expert

Gateway Two is a key aspect of building safety and quality. However, the Building Safety Regulator’s (BSR) approval process is causing significant backlogs in UK construction projects. While...

Read more

How to Turn Around a Delayed Construction Project

Construction delays happen even to the best teams. You don’t have to panic when your employees encounter them. Understanding how construction teams turn around delayed projects will help you plan for...

Read moreHow compliance-driven design can undermine performance

Building regulations, safety standards and sector-specific codes are essential for ensuring that structures are safe, accessible, and environmentally responsible. However, an overreliance on...

Read more

Why Precast Concrete is a Top Choice for 2026 Construction

Custom home construction requires building complex infrastructure that will last while staying within a reasonable budget. Precast concrete emerges as one of the best materials to utilize in your...

Read moreUtilities consultants: providing the vital support every construction project needs

The UK’s cost of living crisis is adding significant financial challenges for everyone across the built environment, not least property developers and builders. While utilities consultants can’t do...

Read more

Why cutting down trees will not solve the UK’s subsidence crisis

Across the UK, thousands of healthy, mature trees are being cut down each year in the name of protecting homes from subsidence. The issue is especially acute in the clay areas of southern England,...

Read more