This is the place for the best construction news

Talk.Build delivers the best and latest construction news and in-depth analysis, shaping your understanding of the ever-evolving building industry. This is the best construction news with updates daily. Even better - check out The Feed for construction news in real time from across the globe.

Here's what sets us apart:

- Groundbreaking construction News: Dive deep into the future of construction with coverage of groundbreaking technologies, industry trends, and policy insights.

- Latest construction news: React swiftly to market shifts and policy changes with instant access to breaking construction news impacting the entire sector.

- Informed construction news decisions: Make data-driven choices with our comprehensive coverage of landmark project announcements.

- Tailored Content: Discover construction news relevant to your area of expertise, whether you're a contractor, architect, engineer, or simply a construction enthusiast.

- Streamlined Experience: We cut through the clutter, delivering construction news bites that matter most to you.

- Extensive Archive: Explore hundreds of ongoing construction news stories and utilize our search bar to find specific topics.

BEMS market performance in Q1 2025 indicates promising future

Illustrating the increased focus on sustainability and utilising technology to reduce energy consumption, the building energy management systems (BEMS) market saw an 8.4% quarter-on-quarter increase...

Read more

Kohler Mira scoop two awards for customer support

As a company that takes great pride in its exceptional customer service and support, Kohler Mira is thrilled to announce it won two highly sought-after awards at this year’s South West Contact...

Read more

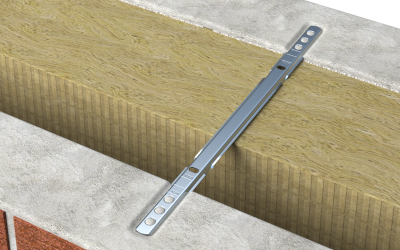

Keyfix combines innovation and quality with launch of new Wall Ties and Fixings range

As an organisation renowned for innovation and ensuring stronger, safer, and smarter construction solutions, Keyfix – part of the Keystone Group – is proud to launch its unique new range of Wall Ties...

Read more

New online Innovation Hub Launched to showcase cutting-edge products

A new Innovation Hub, developed by the Finishes and Interiors Sector (FIS) officially launches this month, to redefine how innovation is discovered, shared and adopted across the finishes and...

Read more

Mira launch new energy efficient shower

Mira Showers is delighted to introduce the new Mira Vista HeatloopTM – an innovative and stylish electric shower specially designed to work in combination with waste water heat recovery for showers...

Read more

CIC commits to Conflict Avoidance Pledge to Champion Collaborative Working in the Built Environment

The Construction Industry Council (CIC) is pleased to share our continued commitment to collaborative working by signing up to the Conflict Avoidance Pledge. The pledge is a key initiative of the...

Read more