The unexpected life of a concrete truck driver

Concrete is the most used man-made material on the planet. Every major city, road, bridge, and housing development depends on a reliable supply. While architects, engineers and contractors often take the spotlight, there is another figure without whom no pour could happen - the concrete truck driver. They occupy a unique position in the construction supply chain - part operator, part logistics manager, part problem-solver - and their work unfolds in an environment where timing, precision and adaptability are critical.

From the outside, the role seems straightforward. A driver arrives at the batch plant, loads a drum with fresh concrete and delivers it to the job site. In reality, this is a complex, tightly choreographed process. Concrete begins to set as soon as the ingredients are mixed and most mixes must be delivered and placed within a strict window - often around ninety minutes - before it loses workability. A driver is responsible for making sure the load reaches its destination in optimum condition, regardless of traffic, weather, or unforeseen delays.

Their work is not simply about moving from point A to point B. Each trip requires monitoring the drum’s rotation speed to keep the concrete agitated without over-mixing, checking consistency and sometimes adding water or admixtures on site to meet the specification. They must also interpret delivery instructions, liaise with site supervisors and adapt to conditions on the ground.

The working day for many concrete truck drivers starts early, often before sunrise. Plants operate to match the construction industry’s preference for early pours, especially in warm climates where cooler morning temperatures help control curing. The driver’s first task is a thorough pre-trip inspection. This includes checking fluid levels, brakes, tyres and the hydraulic system that powers the drum. Safety is paramount, because a vehicle carrying several tonnes of concrete represents a significant hazard if poorly maintained.

Once cleared, the driver positions the truck under the plant’s loading chute. The plant operator manages the batching process, weighing cement, aggregates and water, then discharging them into the drum in a set sequence. Drivers are responsible for confirming that the correct mix design has been loaded, as different projects may require variations in strength, slump and additives such as retarders or accelerators.

As soon as the load is complete, the clock starts. The drum is kept turning at a set speed to keep the mix uniform and the driver receives delivery paperwork and instructions. This is the moment when planning meets unpredictability.

Navigating the roads with a time-sensitive load

Driving a concrete truck is unlike handling most other heavy goods vehicles. The load is constantly moving, and the vehicle’s centre of gravity shifts with every turn and slope. Drivers must account for the extra momentum when braking and cornering, particularly on uneven or congested roads. Sudden stops or sharp turns risk not only spilling the load but damaging the truck or endangering other road users.

Urban deliveries present their own challenges. Construction sites in city centres are often hemmed in by traffic restrictions, narrow streets and limited turning space. In rural areas, drivers may navigate long distances, steep gradients, or unpaved access roads. Regardless of location, time is always pressing. Every minute spent in traffic eats into the delivery window, and drivers must constantly balance speed with safety.

Reaching the site does not mean the job is over. In many ways, it is where the driver’s technical skills become most apparent. Before discharge, the driver checks the slump of the concrete - a measure of its consistency - often using a visual assessment or a quick test. If the mix is too stiff, they may add water within allowable limits, recording any adjustments for quality control. Too much water can weaken the finished concrete, so judgement and experience are essential.

The discharge process varies depending on site requirements. Some projects use chutes directly from the truck into formwork. Others require pumps to move the concrete over long distances or heights. The driver must position the vehicle for safe access, sometimes reversing into tight spaces. They operate the controls that tilt the drum and manage the flow, ensuring an even, continuous pour without segregation of the mix.

Concrete placement can be disrupted by site readiness, equipment breakdowns, or sudden weather changes. In these situations, the driver must liaise with site managers and the plant to decide whether to wait, adjust the mix, or return with the load if it is no longer usable.

The job involves more than sitting behind the wheel. Drivers climb onto their vehicles to wash out drums, attach chutes and inspect loads. They handle heavy equipment, navigate slippery or uneven surfaces and work in all weather conditions. Personal protective equipment - hard hats, high-visibility clothing, gloves and safety boots - is standard and adherence to safety protocols is non-negotiable.

Concrete itself presents hazards. Wet cement is caustic and can cause skin burns. Moving parts on the truck, particularly the rotating drum and hydraulic mechanisms, can injure the unwary. Drivers must remain alert and disciplined, especially during long shifts.

Communication and coordination

A concrete truck driver operates within a chain of coordination that includes dispatchers, batch plant operators and site foremen. Accurate communication is essential. Delays or changes in schedule can require rapid adjustments to the delivery sequence and drivers often relay updates from site back to the plant to help manage production flow.

Modern fleets are equipped with GPS tracking and digital dispatch systems, enabling real-time updates on location and load status. However, technology does not replace the need for clear, practical dialogue. Drivers must convey technical information, such as mix adjustments or site access issues, in a way that allows quick decision-making.

Over time, experienced drivers develop an intuitive sense for concrete behaviour. They learn to anticipate how a mix will respond to weather, transport time and placement method. They understand the impact of temperature on setting time, the signs of segregation and the subtle changes in drum sound that indicate consistency.

This expertise is not formally recognised in the same way as engineering qualifications, yet it is critical to quality control. A poorly handled delivery can compromise the structural integrity of the finished work, leading to costly repairs or even safety risks.

Concrete production and transport are subject to environmental regulations covering dust suppression, water run-off and noise. Drivers are also responsible for ensuring wash water from cleaning drums and chutes is contained and disposed of properly, preventing contamination of drains and waterways.

Vehicle emissions standards also affect operations, particularly in low-emission zones where older trucks may be restricted. Companies increasingly invest in modern, cleaner fleets and drivers must adapt to the handling and maintenance of newer vehicles, including those with hybrid or alternative fuel systems.

Unpredictable days and problem-solving

No two days are alike. Deliveries can be disrupted by breakdowns, plant outages, last-minute order changes, or sudden site closures. Drivers must think on their feet, sometimes re-routing to alternative sites or returning loads for reprocessing.

Concrete truck drivers work in a role that sits at the intersection of logistics, manufacturing and construction. They often form part of the informal network that keeps projects moving, exchanging information with site crews, suppliers and other drivers.

There is a camaraderie in the profession, shaped by shared experiences of early starts, tight deadlines and demanding conditions. Many drivers take pride in seeing the tangible results of their work - knowing that the bridge, hospital, or school they helped supply will stand for decades.

The work of a concrete truck driver is often invisible outside the industry. Yet without their skill and reliability, the construction supply chain would falter. They balance the precision of manufacturing with the unpredictability of fieldwork, ensuring that one of the world’s most important materials arrives where it is needed, in the right condition and on time.

The combination of technical knowledge, logistical planning, and physical resilience makes the role far more complex than it appears. It is a profession that demands attention to detail, a capacity for rapid decision-making, and a commitment to safety under constantly changing conditions.

Their contribution often goes unnoticed, yet the physical structures that shape modern life depend on their expertise. Recognising the hidden challenges and skills involved in the role not only honours the individuals who perform it but also underscores the complexity of the construction supply chain as a whole. In a world where the focus is often on the finished product, the story of how materials arrive and the people who make that happen, remains one of the industry’s most important, if least told, narratives.

Additional Articles

Why modern builders still use tools invented thousands of years ago

Walk onto a modern construction site and you will see plenty of laser levels, drones, tablets and power tools. Yet look a little closer and something unexpected becomes clear. Alongside all this...

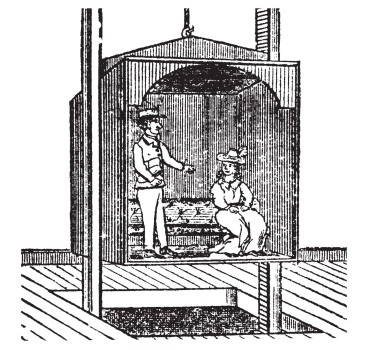

Read moreThe elevator that changed the world when Elisha Otis cut the rope

Today, stepping into a lift is one of the most routine acts of modern life. We press a button, glance at the floor indicator, and trust, almost without thinking. that a metal box will safely carry us...

Read more

How the Romans invented central heating

Central heating feels like a modern convenience, yet its core principles were mastered nearly two thousand years ago. Long before boilers, radiators and underfloor heating systems, the Romans...

Read more