The evolution of energy-efficient windows

The humble window has undergone a remarkable transformation from a simple aperture to a sophisticated technological marvel. Today's windows are no longer mere openings in walls, but sophisticated systems that significantly impact energy efficiency, comfort and building aesthetics.

Historically, windows were basic apertures covered with materials like animal skins or wooden shutters. As societies progressed, glass emerged as a more effective barrier against the elements. However, early glass was often thick, heavy and prone to breakage, until the Industrial Revolution brought advancements in glass manufacturing, leading to larger, clearer panes. However, these early windows offered limited insulation and energy efficiency.

The concept of insulating glass units (IGUs), or double glazing, marked a significant leap forward. By creating a sealed space between two panes of glass, IGUs dramatically improved a window's thermal performance. This innovation reduced heat transfer, enhancing both winter warmth and summer coolness.

The earliest forms of double glazing can be traced back to Victorian Scotland. To combat the harsh winters, homeowners experimented with secondary glazing, often using clay to secure a second layer of glass to their existing windows. This rudimentary form of insulation provided some improvement in thermal efficiency.

However, it was the 1930s that marked a significant turning point. American refrigeration engineer, Charles D. Haven, is credited with inventing the double glazing we recognise today. His 'Thermopane' system introduced two panes of glass separated by a dehumidified air gap, sealed around the edges. While announced in 1932, manufacturing challenges and the subsequent World War II delayed its widespread adoption until the late 1940s.

It wasn't until the 1970s energy crisis that double glazing truly took off. As the cost of energy soared, homeowners sought ways to improve insulation. The combination of this economic pressure with advancements in manufacturing led to a rapid increase in the popularity of double glazing.

By the 1980s, double glazing had become a standard feature in many new homes, and the technology continued to evolve with the introduction of gas-filled units and low-E coatings.

The Role of Gas Fills

The evolution of energy-efficient glazing is inextricably linked to the introduction of gas fills. While the concept of sealed units, or double glazing, was a significant step forward, it was the subsequent innovation of filling the cavity with inert gases that truly revolutionised window performance.

The idea of utilising gas fills emerged in the latter half of the 20th century as energy efficiency became a paramount concern. Scientists and engineers recognised that replacing the air between the glass panes with a gas possessing lower thermal conductivity could dramatically enhance insulation properties. Argon, due to its abundance and relatively low cost, was initially the gas of choice.

The process involves meticulous sealing of the glass units to prevent gas leakage. Once sealed, the gas is introduced into the cavity, creating a barrier that significantly reduces heat transfer. This technological advancement led to a noticeable improvement in window performance, contributing to reduced energy consumption and enhanced indoor comfort.

As research progressed, it was discovered that even more thermally efficient gases could be employed. Krypton, while more expensive, offers superior insulating properties compared to argon. This led to the development of premium-grade double-glazed units that set new benchmarks in energy efficiency.

By reducing heat transfer, these windows also contribute to noise reduction and condensation control. This holistic approach to window performance has solidified the role of gas fills as an essential component of modern energy-efficient glazing.

While subsequent innovations, such as low-emissivity coatings and triple glazing, have further enhanced window performance, the foundation laid by gas fills remains indispensable. As the drive for sustainability intensifies, it is likely that ongoing research will explore even more advanced gas fills and sealing technologies to push the boundaries of energy efficiency in glazing.

Low-E Coatings

Prior to gas fills, the development of low-emissivity (Low-E) coatings was a game-changer. Applied to the surface of the glass, these coatings create a reflective barrier that reduces heat transfer while allowing visible light to pass through. Low-E coatings can be designed to reflect heat back into the living space during winter, maximizing energy efficiency, or to reflect heat away from the building during summer, minimizing cooling loads.

For regions with extreme climates, triple glazing also offers an additional layer of insulation. By incorporating a third pane of glass and filling the spaces with inert gas, triple-glazed windows provide exceptional thermal performance. While the initial cost is higher, the long-term energy savings can offset the investment, but where do we go from here?

The evolution of window technology continues at a rapid pace. Smart glass, capable of adjusting its transparency or opacity in response to light conditions or user preferences, is becoming increasingly common. Self-cleaning glass, equipped with special coatings that break down dirt and grime, reduces maintenance efforts.

As we look to the future, we can anticipate even more innovative window technologies. Solar-powered windows that generate electricity, windows with integrated sensors for monitoring indoor air quality and windows that can adapt to changing climate conditions are all possibilities.

Furthermore, advances in materials science may lead to the development of even more durable, energy-efficient, and sustainable window products. By combining these innovations with smart home technologies, windows could become integral components of a holistic approach to building performance.

So, we can see that the evolution of windows from simple openings to sophisticated technological marvels is a testament to human ingenuity. As we strive for greater energy efficiency, sustainability and comfort, windows will continue to play a vital role in shaping the built environment. By embracing innovation and addressing the challenges of the future, the window industry can contribute to a more sustainable and resilient world.

Additional Articles

Why modern builders still use tools invented thousands of years ago

Walk onto a modern construction site and you will see plenty of laser levels, drones, tablets and power tools. Yet look a little closer and something unexpected becomes clear. Alongside all this...

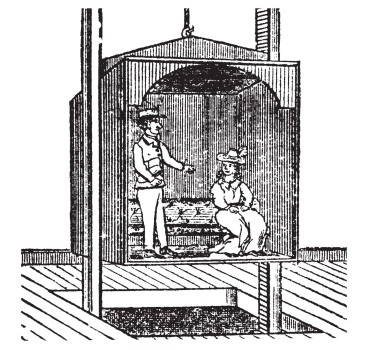

Read moreThe elevator that changed the world when Elisha Otis cut the rope

Today, stepping into a lift is one of the most routine acts of modern life. We press a button, glance at the floor indicator, and trust, almost without thinking. that a metal box will safely carry us...

Read more

How the Romans invented central heating

Central heating feels like a modern convenience, yet its core principles were mastered nearly two thousand years ago. Long before boilers, radiators and underfloor heating systems, the Romans...

Read more