Additional Articles

Why modern builders still use tools invented thousands of years ago

Walk onto a modern construction site and you will see plenty of laser levels, drones, tablets and power tools. Yet look a little closer and something unexpected becomes clear. Alongside all this...

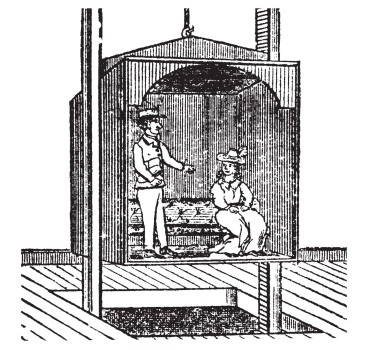

Read moreThe elevator that changed the world when Elisha Otis cut the rope

Today, stepping into a lift is one of the most routine acts of modern life. We press a button, glance at the floor indicator, and trust, almost without thinking. that a metal box will safely carry us...

Read more

How the Romans invented central heating

Central heating feels like a modern convenience, yet its core principles were mastered nearly two thousand years ago. Long before boilers, radiators and underfloor heating systems, the Romans...

Read more