Exoskeletons that will transform construction

We have all seen the “Terminator” films and “Iron “Man” where it is possible to do some amazing things. Just think what could happen if you were able to lift heavier materials, reduce muscle strain and work for more hours without fatigue. Well, it is no longer science fiction – it's the reality of exoskeletons, wearable robotic suits that are poised to revolutionise construction work.

Exoskeletons are already changing the lives of the disabled, they are helping military personnel achieve enormous feats of endurance and they are being widely seen in pilot projects across the world. How long before they become an accepted part of the construction industry?

Companies like Ekso Bionics are leading the development of exoskeletons that could be specifically designed for construction tasks. These innovative suits provide upper body support, reducing strain on worker muscles during activities such as lifting. Think drywall, roofing materials, or concrete blocks. Construction workers spend a significant amount of time lifting and carrying heavy objects so what is there not to like about exoskeletons, which can significantly reduce the strain on backs and shoulders.

Installing ceilings, electrical wiring, or ductwork often requires workers to hold their arms in awkward positions for extended periods. Exoskeletons can provide much-needed support and reduce fatigue. Likewise, drills, saws and other power tools can be heavy and cumbersome to use, especially for long stretches. Exoskeletons can help stabilise the arms and reduce the risk of repetitive strain injuries.

As well as doing all the hard work, the integration of exoskeletons in construction offers a multitude of other benefits. Musculoskeletal injuries are a major concern in construction due to repetitive lifting and awkward postures. By providing support and reducing strain, exoskeletons can help prevent back pain, shoulder injuries and other work-related ailments.

The supportive nature of exoskeletons also helps conserve energy during demanding tasks. This translates to reduced fatigue, allowing workers to maintain focus for longer periods.

Exoskeletons can also potentially improve worker productivity by enabling them to lift heavier materials or work for longer durations without experiencing fatigue. This can lead to faster project completion times and cost savings for construction companies.

At a time when the construction industry faces an aging workforce, exoskeletons can also empower older workers to continue working safely and productively by mitigating the physical demands of the job.

On their own, exoskeletons represent just one aspect of a broader trend towards technological advancements in construction. As this technology matures and becomes more cost-effective, we can expect wider adoption of exoskeletons specifically designed for various construction applications, such as steel framing, masonry work and demolition

Before that happens, proper training will be essential to ensure workers understand the safe and effective use of exoskeletons. They will need to be seamlessly integrated into existing workflows to maximise their benefits – and this might involve adjustments to work practices and safety protocols.

While widespread use in construction is still on the horizon, the concept is here to stay. Iron Mountain, a data storage company, has used Ekso Bionics exoskeletons to reduce worker strain during the installation of heavy servers in their data centres. The results? A significant decrease in worker fatigue and a safer work environment, demonstrating the potential benefit for similar heavy lifting tasks within construction.

Ford Motor Company partnered with Ekso Bionics to explore the use of exoskeletons on their assembly lines. The goal? To reduce worker strain and improve ergonomics during physically demanding tasks. The learnings from this collaboration can be directly applied to similar tasks within the construction industry, such as lifting or installing heavy machinery.

So we can see, Exoskeletons offer a glimpse into a future where construction work is safer, less physically demanding and potentially more productive. It cannot be much longer before we embrace these innovations to create a construction industry that prioritises worker well-being and paves the way for a more sustainable and efficient future.

Sources:

- Ekso Bionics Website: https://eksobionics.com/

- "Ekso Bionics Announces Collaboration with Iron Mountain to Pilot EksoNR Exoskeleton to Reduce Worker Strain" (Ekso Bionics Press Release): https://eksobionics.com/past-products/

- "Ford and Ekso Bionics Partner to Explore Exoskeleton Technology to Enhance Worker Ergonomics" (Ekso Bionics Press Release): https://eksobionics.com/

Additional Articles

Why modern builders still use tools invented thousands of years ago

Walk onto a modern construction site and you will see plenty of laser levels, drones, tablets and power tools. Yet look a little closer and something unexpected becomes clear. Alongside all this...

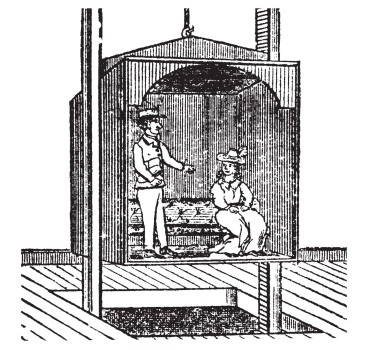

Read moreThe elevator that changed the world when Elisha Otis cut the rope

Today, stepping into a lift is one of the most routine acts of modern life. We press a button, glance at the floor indicator, and trust, almost without thinking. that a metal box will safely carry us...

Read more

How the Romans invented central heating

Central heating feels like a modern convenience, yet its core principles were mastered nearly two thousand years ago. Long before boilers, radiators and underfloor heating systems, the Romans...

Read more