Global Prefabricated Buildings Market Poised for Unprecedented Growth

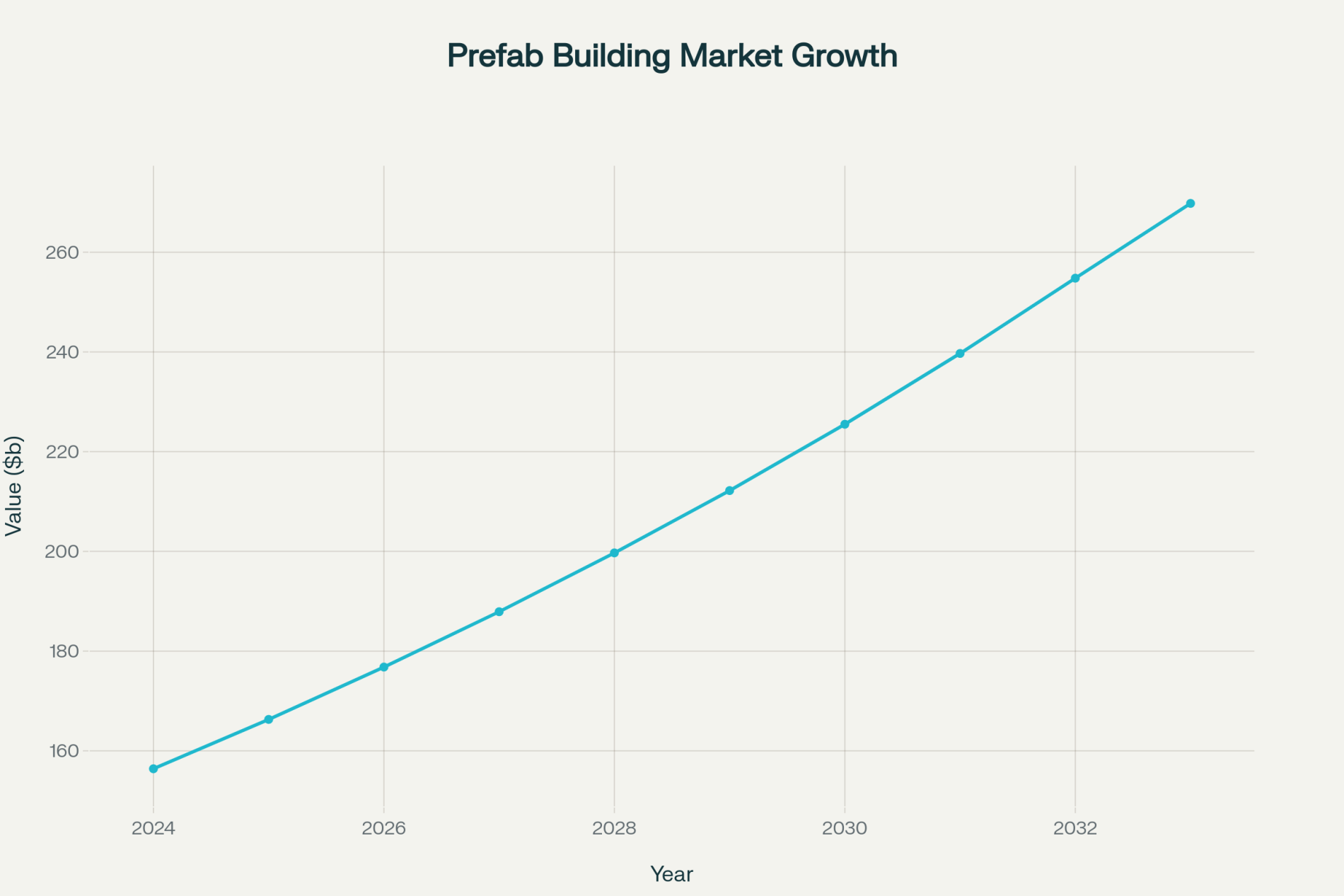

Market Intelo's comprehensive 2033 market research report unveils transformative growth trajectory driven by digital innovation, sustainability mandates, and rapid urbanization across global markets. The global prefabricated buildings market is experiencing a revolutionary transformation, with new market intelligence revealing unprecedented growth potential that positions the industry as a cornerstone of modern construction. According to Market Intelo's latest comprehensive research report, the Global Prefabricated Buildings Market Research Report 2033, the industry is forecasted to expand from $156.4 billion in 2024 to $269.8 billion by 2033, representing a robust compound annual growth rate (CAGR) of 6.3%.

This market surge reflects a fundamental shift in construction methodologies, driven by the convergence of digital transformation, sustainability imperatives, and the urgent need for cost-effective, time-efficient building solutions across both developed and emerging economies. The research encompasses comprehensive analysis across multiple market segments, including modular, panelized, pre-cut, and manufactured building types, utilizing materials ranging from steel and concrete to innovative wood-based solutions.

Global Prefabricated Buildings Market Growth Forecast (2024-2033)

Revolutionary Market Dynamics Reshaping Construction Industry

The prefabricated buildings sector is undergoing profound transformation as industry stakeholders embrace cutting-edge technologies and sustainable construction practices. Building Information Modeling (BIM), advanced robotics, and IoT-enabled monitoring systems are revolutionizing the design, manufacturing, and assembly processes of prefabricated structures, enabling precision engineering while minimizing material wastage and significantly reducing project timelines.

Market intelligence indicates that modular construction accounts for nearly 40% of total market revenue in 2024, driven by widespread adoption across residential and commercial projects. This dominance stems from modular construction's versatility, scalability, and ability to reduce construction timelines by 30% to 50% compared to traditional methods. The approach allows entire building sections to be fabricated off-site in controlled environments, then assembled on-site with remarkable efficiency and quality consistency.

The growing emphasis on green construction and energy efficiency standards is compelling developers to embrace prefabricated solutions, which typically generate up to 90% less waste than conventional construction methods and offer superior insulation properties. This alignment with global sustainability agendas positions prefabricated buildings as essential infrastructure for meeting climate targets and environmental regulations.

Modern prefabricated building showcasing sleek design with large glass windows and wood-metal facade illuminated at dusk.

Regional Market Leadership and Explosive Growth Patterns

North America commands the largest market share at over 32% in 2024, driven by mature construction industries in the United States and Canada, high labor costs, and robust sustainability frameworks. The region's dominance is reinforced by widespread adoption of modular construction techniques, particularly in commercial and institutional sectors where schools, healthcare facilities, and corporate offices increasingly utilize off-site construction methods.

However, Asia Pacific emerges as the fastest-growing regional market with a projected CAGR of 8.1% through 2033. This exceptional growth trajectory is fueled by rapid urbanization, expanding middle-class populations, and ambitious infrastructure development programs across China, India, Japan, and Southeast Asian nations. Government initiatives promoting green building practices, coupled with massive investments in smart cities and industrial corridors, are catalyzing unprecedented market expansion.

Recent market data reveals that India's prefabricated buildings market alone is expected to grow from $2.70 billion in 2024 to $5.47 billion by 2030, representing a remarkable 12.32% CAGR. This growth is supported by government programs including the Smart Cities Mission and Pradhan Mantri Awas Yojana (PMAY), which have sanctioned 2.94 crore houses with 2.62 crore completions as of June 2024.

Material Innovation Driving Market Differentiation

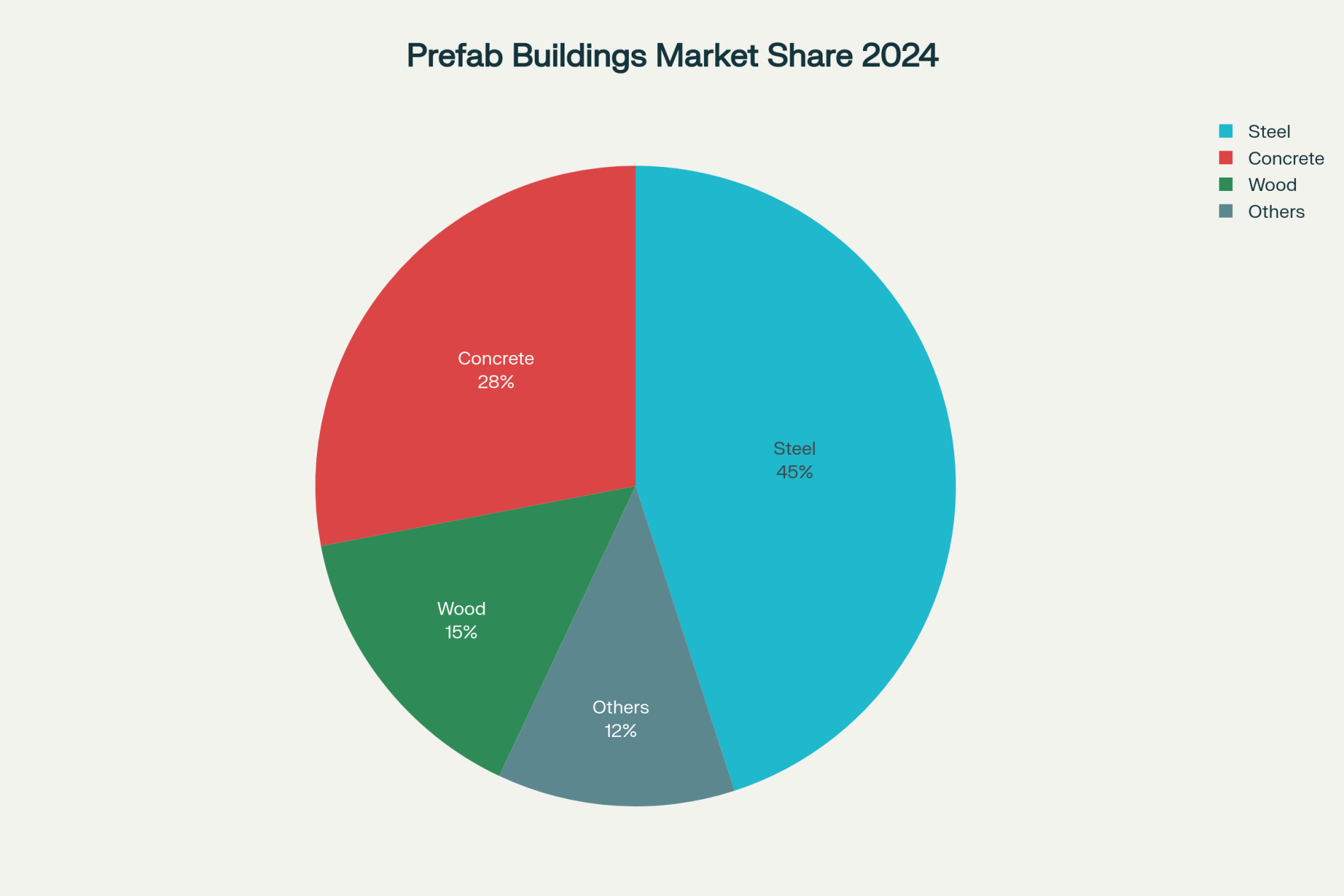

Steel dominates the material segment with over 45% market share, valued for its strength-to-weight ratio, durability, and suitability for large-scale modular structures. Steel-based prefabricated buildings are extensively deployed in commercial, industrial, and institutional applications where structural integrity and fire resistance are paramount. The material's popularity is reinforced by recent innovations in steel frame modular construction, including hurricane-resistant designs and rapid deployment capabilities.

Concrete represents the second-largest material segment, prized for thermal mass, acoustic properties, and longevity in high-rise residential and infrastructure projects. Meanwhile, wood is experiencing renewed attention as a sustainable material, particularly with advances in engineered wood products such as cross-laminated timber (CLT) and glue-laminated timber (glulam) that expand applications to mid-rise and high-rise structures.

The "others" category encompasses innovative materials including composites, recycled plastics, and hybrid systems designed to enhance performance while reducing environmental impact. Material innovation serves as a key competitive differentiator, with companies investing substantially in research and development for lighter, stronger, and more environmentally friendly prefabricated components.

Prefabricated Buildings Market Share by Material Type (2024)

Technology Integration Accelerating Industry Evolution

Digital transformation stands as the primary catalyst for market growth, with advanced technologies revolutionizing every aspect of prefabricated construction. The integration of artificial intelligence (AI) and Internet of Things (IoT) systems enables real-time monitoring, predictive maintenance, and optimization of construction projects, significantly reducing costs and improving efficiency.

3D printing technology is gaining traction in prefabrication processes, enabling production of custom building components with unprecedented precision. This technology is particularly beneficial for complex architectural designs, providing cost-effective solutions for intricate structures that were previously challenging or expensive to manufacture.

Robotics and automation are streamlining prefabrication processes by automating repetitive tasks including welding, cutting, and component assembly. Companies like Automated Architecture (AUAR) are utilizing robotic arms and proprietary software to construct timber-framed homes with remarkable precision, reducing construction time from months to weeks. These technological advances address persistent labor shortages while improving safety standards and construction quality.

An automated robotic arm assembling prefabricated building components in a modular construction factory.

Sustainability Leadership Defining Market Future

Environmental sustainability has evolved from optional consideration to industry imperative, with 69% of construction stakeholders viewing sustainable practices as a priority. Prefabricated construction aligns perfectly with circular economy principles by minimizing waste, optimizing material usage, and enabling comprehensive recycling programs.

Energy-efficient designs incorporating passive strategies, renewable energy systems, and advanced building materials are becoming standard in prefabricated construction. The integration of smart building technologies, including IoT sensors and AI-driven systems, enables real-time monitoring of energy consumption and resource usage, supporting data-driven sustainability decisions.

The carbon footprint reduction potential of prefabricated construction is substantial, with controlled factory environments enabling precise material management and significantly reduced transportation emissions through localized supply chains. Companies are increasingly investing in carbon offsetting technologies and renewable energy projects to achieve carbon neutrality targets.

A digital rendering of modular building framing systems showing construction of prefabricated units with light gauge steel in a modern facility.

Market Applications Driving Diverse Growth Opportunities

Residential applications capture the largest market segment at over 38% of revenue in 2024, driven by urgent demand for affordable, energy-efficient housing solutions in urban and peri-urban areas worldwide. Multi-family housing, student accommodation, and emergency shelters represent key growth areas supported by government initiatives and public-private partnerships addressing housing deficits.

Commercial applications are expanding rapidly, with prefabricated office spaces, retail outlets, hotels, and mixed-use developments gaining favor among developers seeking accelerated return on investment. The industrial sector leverages prefabrication for scalability and cost efficiency in factories, warehouses, and logistics facilities, while institutional applications including schools, hospitals, and government buildings benefit from construction speed and flexibility.

Recent project achievements demonstrate market capabilities, including Singapore's 40-story residential tower completed in 14 months using modular units—40% faster than traditional methods—and Berlin's Housing for All Program delivering 5,000 affordable units in six months with 30% cost reduction.

Investment Landscape and Market Accessibility

Strategic capital investments from both public and private sectors are reshaping the competitive landscape, with major construction firms channeling resources into advanced manufacturing facilities, research centers, and digital platforms. The entry of specialized startups and technology companies is intensifying competition while spurring product innovation across material science, manufacturing processes, and assembly techniques.

Funding rounds and capacity expansion initiatives are accelerating globally, with European firms increasing manufacturing capacity for prefabricated homes, North American companies scaling operations to meet housing demand, and Middle Eastern developers providing prefabricated data center facilities for cloud services.

Future Outlook and Strategic Implications

The modular construction market is projected to reach $221.8 billion by 2035 with a 7.65% CAGR, indicating sustained long-term growth beyond the current forecast period. This trajectory is supported by technological advancements including AI-driven design optimization, digital twin implementation, and expanded infrastructure applications.

Regional diversification presents significant opportunities, with Latin America, Middle East, and Africa emerging as high-potential markets driven by regulatory reforms, demographic trends, and economic diversification efforts. Government infrastructure investments and housing programs in these regions create substantial demand for rapid, cost-effective construction solutions.

The integration of smart city initiatives and disaster relief applications expands market scope beyond traditional construction, positioning prefabricated buildings as essential components of resilient, adaptable infrastructure systems. As climate challenges intensify, the industry's ability to provide rapid deployment solutions for emergency housing and infrastructure repair becomes increasingly valuable.

Conclusion

The global prefabricated buildings market represents a transformative force in modern construction, combining technological innovation, environmental sustainability, and economic efficiency to address critical infrastructure challenges. With robust growth projections, expanding regional markets, and continuous technological advancement, the industry is positioned to play a central role in meeting global housing needs while supporting climate targets and sustainable development goals.

Additional news

GOLDBECK and Prime partner to deliver vital key worker housing in Dorchester

GOLDBECK, a leading European construction and development company that focuses on systemised, industrialised building methods and Prime plc, a UK-based specialist developer of health and care...

Read more

Major industry leaders join DataScope in shining spotlight on construction health and safety

The vital roles data and technology can play in enhancing construction site safety saw industry leaders come together for a thought-provoking health and safety insights event, hosted by DataScope.

Read more