The true cost and value of ‘green’ materials for small construction projects

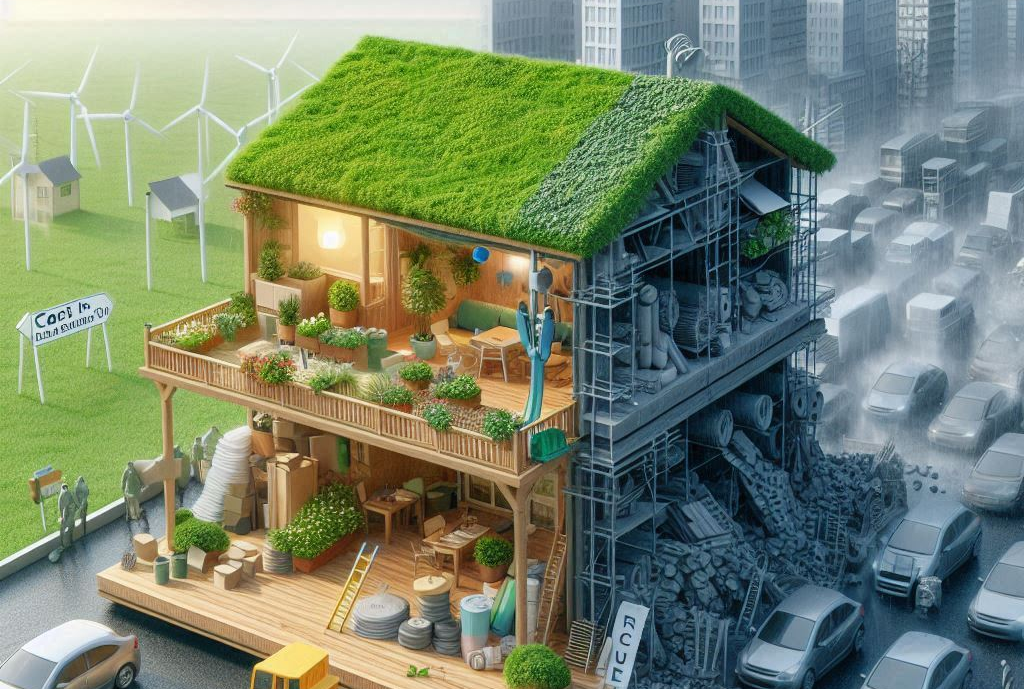

What do we really mean by the term "green materials". It's plastered across marketing brochures, touted at industry events and often perceived as an exclusive domain for large, high-budget projects aiming for ambitious certifications. However, for smaller contractors, the majority of businesses that form the backbone of our industry, the idea of embracing sustainable materials can often feel like a distant, expensive luxury, laden with jargon and hidden costs that seem beyond reach. This perception, fuelled by marketing hype and the often-complex world of environmental certifications, unfortunately obscures the genuine, practical and often cost-effective benefits that 'green' choices can offer, even on the smallest of projects, writes John Ridgeway.

The truth is, integrating sustainable materials is not just about chasing a LEED plaque or achieving a BREEAM rating, especially for modest residential renovations or small commercial fit-outs. It's about making sensible, long-term decisions that benefit the client, the environment and critically, the contractor's bottom line. The "true cost" of a material extends far beyond its initial purchase price - it encompasses its entire lifecycle - from extraction and manufacturing to transportation, installation, performance, maintenance, and eventual disposal. Understanding this holistic cost is the first step in moving beyond the hype and truly evaluating the value of a 'green' choice.

Let's dissect the common assumption that 'green' always means 'expensive.' While some highly specialised sustainable materials might indeed carry a premium upfront, many genuinely environmentally friendly options are surprisingly competitive, or offer long-term savings that quickly offset any initial difference. The key is knowing where to look and understanding the subtle distinctions.

For instance, opting for locally sourced timber, even if it's not stamped with a dozen certifications, often reduces transportation costs and carbon footprint compared to exotic imported wood. Its 'green' credentials derive from its proximity and reduced energy in transit, not just a complex verification process. Similarly, choosing recycled content drywall or insulation might offer comparable performance to virgin materials at a similar price point, with the added benefit of diverting waste from landfill.

Going green – the challenge for small contractors

The challenge for smaller contractors lies in navigating the vast and often confusing landscape of certifications. While schemes like FSC for timber, Cradle to Cradle, or Environmental Product Declarations (EPDs) provide valuable data, they can be overwhelming for a small firm with limited time and resources. Instead of focusing on acquiring certified materials for every single element, a more practical approach for smaller projects involves adopting a "conscious choice" methodology. This means prioritising core principles: reducing embodied carbon, minimising waste, improving indoor air quality, enhancing durability and supporting local economies.

Consider the idea of embodied carbon, the total greenhouse gas emissions associated with a material's lifecycle. A high-strength, virgin steel beam might appear cheaper on paper than a recycled steel beam, but the energy required to produce virgin steel is far greater. Waste reduction is another powerful avenue for both environmental and financial savings. A 'green' approach starts on the job site itself. Implementing robust waste segregation, identifying opportunities for material reuse (e.g., repurposing salvaged timber or bricks) and optimising cutting plans to minimise offcuts, can dramatically reduce skip hire costs and landfill fees.

This is not about buying expensive new 'green' products; it's about smarter management of existing ones. For instance, using modular components or prefabricated elements, which might initially seem like an operational strategy rather than a material choice, directly contributes to waste reduction by moving fabrication to a controlled factory environment where offcuts can be managed and recycled more efficiently.

Improving indoor air quality (IAQ) is also a 'green' benefit that directly impacts occupant health and productivity, offering significant value to clients. Many conventional building materials, paints, adhesives and sealants, give off-gas volatile organic compounds (VOCs) for years, contributing to respiratory issues, headaches and a general sense of malaise. Opting for low-VOC or zero-VOC paints, adhesives and sealants is a tangible, often cost-neutral step.

Major manufacturers now offer extensive ranges of low-VOC products at competitive prices, eliminating the need to source specialised, expensive alternatives. Educating clients on the health benefits of such choices can also be a powerful selling point for smaller contractors, differentiating them from competitors.

Materials that last longer

Durability and longevity are arguably the most overlooked 'green' attributes. A material that lasts longer, requires less frequent replacement and stands up better to wear and tear, is inherently more sustainable, regardless of its initial production method. While the upfront cost of a more durable flooring material or a more resilient exterior finish might be slightly higher, the reduced maintenance costs and extended lifespan offer significant savings over the building's lifecycle.

This is a powerful conversation to have with clients who are often focused solely on upfront costs. For instance, investing in high-quality, long-lasting external cladding might cost more than cheaper alternatives, but if it halves the repaint cycle or drastically reduces repair needs over 20 years. The true long-term value is undeniable and aligns perfectly with the adage, "buy once, buy well."

Furthermore, supporting local economies through material procurement is a genuinely 'green' practice that small contractors are uniquely positioned to champion. Sourcing materials from within a reasonable radius not only reduces transportation emissions, but also injects money directly back into the local community, strengthening regional supply chains.

This could mean opting for bricks from a nearby quarry, timber from a regional sawmill, or even aggregate from a local recycling facility. While these might not carry a global environmental certification, their local origin inherently makes them a more sustainable choice compared to materials shipped across continents. Developing relationships with local suppliers can also lead to more competitive pricing and reliable delivery, often circumventing the logistical complexities that larger firms might face with sprawling international supply chains.

The practical implementation of these principles for a small contractor involves a few key steps. First, research and education are paramount. Instead of relying solely on marketing claims, take the time to understand the basic environmental impacts of common materials. Simple online searches for "embodied carbon concrete vs. timber" or "VOCs in paint" can provide valuable insights.

Second, build relationships with knowledgeable suppliers. Many mainstream building material suppliers now have dedicated 'green' product specialists who can offer guidance on sustainable alternatives within specific budget ranges. Don't be afraid to ask about recycled content, low-VOC options, or locally sourced materials.

Third, communicate the value proposition to your client. Frame 'green' choices not just as environmental benefits, but as tangible advantages like lower energy bills, healthier indoor environments, reduced maintenance costs, or enhanced property value. For a homeowner, a durable, low-VOC paint that lasts longer and does not give off-gas harmful fumes is a clear win. For a small business owner, lower operational costs due to better insulation translate directly to profitability.

Going green is simpler than it looks

Consider insulation, a fundamental component of any building. While specialised, high-performance 'green' insulation products exist, a practical 'green' choice for a small project might simply involve specifying a thicker layer of conventional, readily available insulation. The significant energy savings over the building's lifespan and the resulting reduction in operational carbon, arguably outweigh the marginal differences in the embodied carbon of the insulation material itself. This highlights that 'green' is not always about radical new materials - sometimes it's about optimising the use of existing ones for better performance.

Another area ripe for practical 'green' choices is water efficiency. Installing low-flow fixtures, dual-flush toilets and water-efficient appliances does not necessarily involve exotic materials, but it dramatically reduces water consumption, leading to lower utility bills for the client and less strain on local water resources. These are often easy-to-install upgrades that have a clear, quantifiable return on investment.

Ultimately, "Beyond Certification" means adopting a mindset of resourcefulness and responsibility. It's about looking at every material and every process through a lens of efficiency, longevity and minimal impact. It's about challenging conventional wisdom and asking: "Is there a better, smarter way to do this?" For the small contractor, this does not require a dedicated sustainability department or a vast research budget. It requires a willingness to learn, to ask questions and to engage in thoughtful conversations with suppliers and clients.

The true cost of 'green' materials for small projects is not just a number on the books - it's an investment in a more resilient future, healthier spaces and a stronger reputation for the contractor who dares to look beyond the hype. By making informed, practical choices, small construction businesses can not only contribute significantly to a more sustainable built environment, but also unlock new value propositions for their clients, proving that green building is not just for the giants of the industry - it's for everyone.

Additional Blogs

4 Must-Follow Health and Safety Habits for the Modern Jobsite

The risks in modern jobsites are constant. Falls, chemical exposure and heat illnesses continue to injure workers across construction and related industries each year. The best way to reduce those...

Read moreDesigning multi-functional outdoor spaces through the power of Play Trees

Outdoor spaces are increasingly expected to do more than simply look good. They must invite interaction, support wellbeing, encourage movement and foster connection across generations. In schools,...

Read more

4 Ways Resilient Construction Gets it Right and 4 Ways It’s Still Falling Short

Climate change is becoming increasingly disruptive as the weather becomes stronger and more unpredictable. These circumstances are constantly pressuring the construction industry, which has had to...

Read more