Building with bacteria for sustainable construction

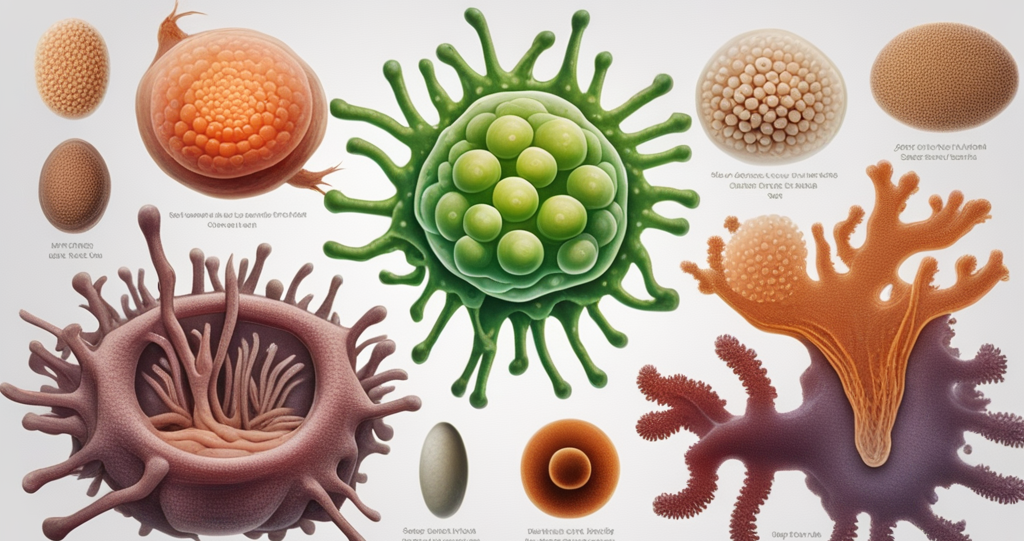

A new wave of innovation is poised to reshape construction - living organisms – and they are set to be the building blocks of the future. Bioconstructive materials, a revolutionary approach to sustainable construction, uses bacteria and other microorganisms to create building materials, to deliver unique and potentially game-changing properties, writes John Ridgeway.

The concept might seem like science fiction, but the science behind bioconstruction is rooted in natural processes. Researchers are working in the area of microbial induced calcite precipitation (MICP), a technique which utilises specific bacteria strains with the ability to precipitate calcium carbonate (the main component of limestone and seashells) in the presence of certain compounds. By introducing these bacteria into a sandy or loose soil mixture, they essentially "glue" the particles together, forming a bio-cement or bio-brick.

Fungal mycelium, which we have highlighted in previous blogs at Talk.Build, is also at the forefront of this technology. Mycelium, is a vegetative network of fungi, which can be grown in moulds filled with organic materials like agricultural waste or woodchips. Once the mycelium network forms, it binds the materials together, creating a lightweight and fire-resistant composite material.

If the researchers can get it right then there is massive potential for this technology. Bio-bricks and other bioconstructive materials could be used for constructing homes, offices and other buildings, offering a more sustainable and potentially even more cost-effective alternative to traditional methods.

Bio-cement could be used for pavements and even self-healing road surfaces, reducing maintenance needs and environmental impact. The rapid growth and lightweight nature of some bioconstructive materials also make them ideal for building temporary shelters or emergency housing following natural disasters.

Benefits of building with living materials

Bioconstructive materials offer a multitude of advantages over traditional construction methods, making them a compelling option for a more sustainable future. For example, traditional construction materials like concrete have a significant carbon footprint associated with their production. Bioconstructive materials, on the other hand, can actually absorb carbon dioxide during their growth, contributing to a net negative carbon footprint.

Some bio-cements have the ability to self-heal cracks, thanks to the ongoing activity of the bacteria. This reduces the need for frequent repairs and extends the lifespan of structures. Bioconstructive materials can also be produced using readily available local materials, reducing transportation costs and the longer-term environmental impact. Furthermore, certain bio-materials possess good insulation properties, leading to more energy-efficient buildings.

However, while bioconstruction offers exciting possibilities, it’s still a developing field with certain challenges. Achieving the same level of strength and durability as traditional materials is still a hurdle.

Current building codes and regulations are also not designed for bioconstructive materials, so we will need standardised testing and certification procedures. In addition, the long-term performance of bioconstructive materials in different environmental conditions is still under evaluation. More research is needed to ensure their longevity.

Inspiration from history

The concept of using living organisms in construction has a surprisingly long history. Ancient Romans used a bacteria-based mortar for some of their structures, and there are even records of civilisations using mycelial networks for building materials.

While it's difficult to pinpoint a single inventor for bioconstruction, the field owes its foundation to the pioneering work of microbiologist Henk Jonkers in the 1990s. His research on bio-cement sparked a wave of interest in this area. Today, numerous research institutions, universities and startups are actively involved in developing bioconstructive materials.

However, the timeline for widespread adoption of bioconstructive materials depends on overcoming various challenges. Over the next 5-10 years, continued research and development are expected to improve the strength, durability, and standardisation of bioconstructive materials. Pilot projects and demonstration buildings will likely become more common. Regulatory frameworks for bio-based materials might also begin to take shape.

With ongoing advancements, bioconstructive materials could become a more cost-competitive option, over a period of 10 to 20 years, compared to traditional materials. Wider adoption in specific applications like non-load-bearing walls or interior structures could become a reality in that time period.

Beyond 20 years is still very much guesswork. Bioconstructive materials might become a mainstream choice for various building types, potentially with self-healing properties and improved life cycles. Sustainable and bio-based construction practices could become the norm.

That said, we can still see some early examples of this technology in practice. The city of Amsterdam developed a temporary bio-brick pavilion. It was unveiled in 2014 and used bio-bricks, grown with the help of bacteria. The project served as a proof-of-concept for the potential of bioconstruction.

The 18 metre Hy-Fi Tower in Milan, built in 2019 used mycelium as the primary building material. The project demonstrated the structural potential of fungi-based materials.A living Seawall Project in the Netherlands, has explored the use of mussel beds and bio-cement to create living seawalls that can adapt to rising sea levels and protect coastlines.

So we can see that bioconstruction represents a massive shift in the way we think about building materials. By harnessing the power of living organisms, we can create a more sustainable and resilient built environment. While challenges remain, the potential benefits of bioconstruction are undeniable. As research and development continue, we can expect to see these living materials playing an increasingly vital role in shaping the future of construction.

Additional Blogs

Construction site safety - is zero tolerance realistic?

Walk onto almost any construction site in the country and you will see it printed in bold letters across hoardings and induction slides: ZERO TOLERANCE. It sounds decisive, reassuring and strong. The...

Read moreIs timber construction really greener - or just trendy?

Over the past decade, timber has enjoyed something close to a renaissance. Architects talk about warmth and biophilic design. Developers highlight carbon storage. Contractors discuss speed of...

Read more

4 Must-Follow Health and Safety Habits for the Modern Jobsite

The risks in modern jobsites are constant. Falls, chemical exposure and heat illnesses continue to injure workers across construction and related industries each year. The best way to reduce those...

Read more